As drilling operations become more complex and demanding, the need for advanced solids control equipment continues to grow. Among the innovative solutions available today, the double deck shale shaker stands out as a powerful tool for enhanced solids separation efficiency. This technology builds upon traditional single-deck designs by adding a second screening layer, allowing for more thorough processing of drilling fluids.

Double deck shale shakers represent a significant advancement in solids control technology, offering improved performance, increased efficiency, and better overall drilling fluid management. In this article, we'll explore the key features, benefits, and applications of double deck shale shaker technology.

Understanding Double Deck Shale Shaker Design

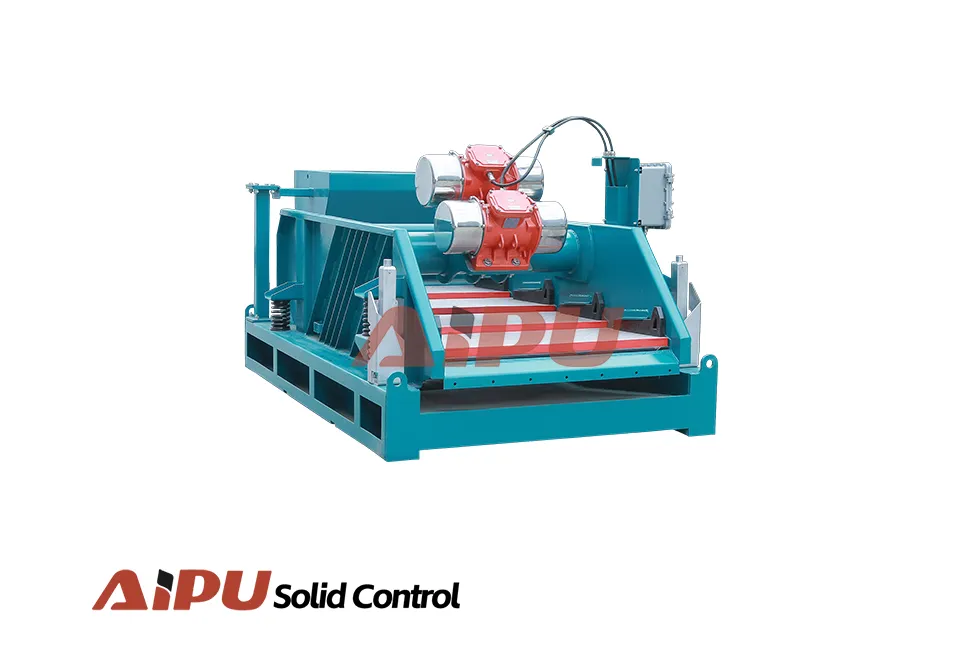

At its core, a double deck shale shaker features two separate screening decks stacked vertically. Each deck is equipped with different mesh size screens, allowing for sequential separation of cuttings by size. The upper deck typically uses a coarser mesh to remove larger particles, while the lower deck employs a finer mesh to capture smaller solids.

This two-stage separation process offers several advantages over traditional single-deck shakers. By removing larger particles first, the lower deck can operate more efficiently, extending screen life and improving overall separation performance.

Key Design Features

Modern double deck shale shakers incorporate several advanced design features to optimize performance:

- Dual Vibratory Mechanisms: Some models feature independent vibratory systems for each deck, allowing operators to adjust vibration intensity and frequency for optimal performance.

- Adjustable Deck Angles: The ability to adjust the angle of each deck independently allows for fine-tuning separation performance based on drilling conditions.

- Quick-Release Screen Systems: Many double deck shakers feature quick-replace screen systems, reducing downtime for screen changes.

- High-G Force Capability: Advanced models can generate high G-forces, enhancing the separation of fine particles.

- Durable Construction: Heavy-duty frames and components ensure reliable performance in harsh drilling environments.

"Double deck shale shakers represent a significant leap forward in solids control technology, offering operators the ability to achieve more efficient separation with a single piece of equipment."

- Drilling Equipment Specialist

How Double Deck Shale Shakers Work

The operation of a double deck shale shaker follows a logical, sequential process:

Stage 1: Initial Separation on the Upper Deck

Drilling fluid containing cuttings enters the shaker through the feed box. The upper deck, equipped with a coarser screen mesh, immediately begins removing larger particles. These large cuttings are discharged off the end of the upper deck for disposal.

Stage 2: Secondary Separation on the Lower Deck

The drilling fluid, now partially cleaned, flows through the upper deck screen onto the lower deck. This deck, fitted with a finer mesh, captures smaller particles that passed through the upper deck. The further cleaned fluid exits the shaker for additional processing or recirculation.

Stage 3: Fluid Recovery and Cuttings Disposal

The cleaned drilling fluid is collected in a pan below the lower deck and directed to the next stage of the solids control system. Meanwhile, the smaller cuttings captured by the lower deck are discharged for disposal.

Benefits of Double Deck Shale Shakers

The double deck design offers several significant advantages over traditional single-deck shakers:

1. Enhanced Separation Efficiency

By employing two stages of separation with different mesh sizes, double deck shakers achieve more thorough solids removal than single-deck models. This results in cleaner drilling fluid and better overall system performance.

2. Increased Throughput Capacity

The dual-deck design allows for higher processing volumes, making double deck shakers ideal for large-scale drilling operations with high fluid flow rates.

3. Extended Screen Life

By removing larger particles first, the lower deck screen experiences less wear and tear, extending its lifespan. This reduces downtime and replacement costs.

4. Improved Drilling Fluid Quality

The two-stage separation process produces cleaner drilling fluid, which can improve drilling performance, reduce fluid-related problems, and extend the life of downstream solids control equipment.

5. Reduced Environmental Impact

More efficient separation means less drilling fluid is lost with cuttings, reducing waste and minimizing the environmental footprint of drilling operations.

6. Cost Savings

The combination of increased efficiency, extended screen life, and reduced fluid loss translates to significant cost savings over the life of the equipment.

Applications of Double Deck Shale Shakers

Double deck shale shakers are well-suited for a wide range of drilling applications, including:

1. Deepwater and Ultra-Deepwater Drilling

These demanding operations require highly efficient solids control to manage complex drilling fluids and minimize environmental risk.

2. High-Pressure High-Temperature (HPHT) Drilling

HPHT drilling generates fine cuttings that require advanced separation technology for effective removal.

3. Horizontal Directional Drilling (HDD)

HDD operations often use high-volume drilling fluid systems that benefit from the increased throughput capacity of double deck shakers.

4. Geothermal Drilling

Geothermal drilling produces abrasive cuttings that can wear out equipment quickly. Double deck shakers with durable construction are ideal for these applications.

5. Mining and Construction Drilling

Large-scale mining and construction projects generate massive volumes of cuttings, making the high throughput of double deck shakers essential.

Choosing the Right Double Deck Shale Shaker

When selecting a double deck shale shaker for your operation, consider the following factors:

- Processing Capacity: Ensure the shaker can handle your expected drilling fluid flow rates.

- Screen Options: Look for models that offer a wide range of screen mesh sizes to accommodate different drilling conditions.

- Vibration Control: Models with adjustable vibration intensity and frequency offer greater flexibility.

- Maintenance Requirements: Consider the ease of maintenance and availability of replacement parts.

- Durability: Choose a model with heavy-duty construction for reliable performance in harsh environments.

- Manufacturer Support: Select a reputable manufacturer with a proven track record and strong customer support.

Conclusion

Double deck shale shaker technology represents a significant advancement in solids control, offering operators improved performance, increased efficiency, and better overall drilling fluid management. By incorporating two screening stages into a single unit, these shakers provide enhanced separation capabilities that can help reduce costs, improve drilling performance, and minimize environmental impact.

As drilling operations continue to evolve and become more challenging, double deck shale shakers will likely play an increasingly important role in modern solids control systems. Their ability to handle high volumes, separate a wide range of particle sizes, and operate efficiently in harsh conditions makes them an invaluable asset for any drilling operation seeking to optimize performance and reduce costs.