In the world of drilling solids control, the performance of a shale shaker is often measured by its ability to efficiently separate solids from drilling fluid. One of the key factors that determines this efficiency is the G-force generated by the equipment. Modern shale shakers are designed with high-G force capabilities, which have revolutionized solids separation in various drilling applications.

High-G force refers to the multiple of gravitational acceleration (g) that the shale shaker imparts on the drilling fluid and cuttings. Traditional shale shakers typically operated at G-forces between 6G and 8G, while modern high-performance models can reach up to 12G or even higher. This increase in G-force has significant implications for drilling operations.

How High-G Force Improves Shale Shaker Performance

The primary benefit of high-G force in shale shakers is improved solids separation efficiency. When drilling fluid and cuttings are subjected to higher G-forces, the heavier solid particles are more effectively separated from the fluid. This results in cleaner drilling fluid being returned to the active system, which has several advantages:

Enhanced Solids Removal

High-G force allows the shale shaker to remove finer particles from the drilling fluid, reducing the load on downstream solids control equipment such as desanders and centrifuges. This not only improves overall system efficiency but also extends the lifespan of these more expensive components.

"High-G force technology has enabled drilling operations to achieve solids removal efficiencies that were previously unattainable, leading to significant cost savings and improved drilling performance."

Reduced Fluid Loss

With more effective solids separation, less drilling fluid is lost with the discarded cuttings. This is particularly important in environments where drilling fluid costs are high or where environmental regulations limit fluid discharge. High-G force shale shakers can recover up to 15% more drilling fluid compared to traditional models, resulting in substantial cost savings over the course of a drilling project.

Improved Drilling Fluid Properties

Cleaner drilling fluid maintains its properties better, providing more effective lubrication and cooling for the drill bit. This can extend bit life and improve drilling rates, further reducing operational costs. Additionally, cleaner fluid reduces the risk of stuck pipe and other drilling problems associated with contaminated fluid.

Adaptability to Challenging Conditions

High-G force shale shakers are better equipped to handle challenging drilling conditions, such as high-viscosity fluids or sticky clays. The increased force helps to break up agglomerated particles and prevent screen blinding, ensuring consistent performance even in the most demanding environments.

Considerations for High-G Force Shale Shakers

While high-G force offers numerous benefits, there are important considerations for operators when selecting and using these systems:

- Screen Selection: High-G force places greater stress on shaker screens, so selecting the appropriate screen material and mesh size is crucial for optimal performance and longevity.

- Maintenance Requirements: The increased vibration from high-G force may require more frequent maintenance of components such as motors, springs, and screens.

- Adjustable G-Force: Many modern shale shakers allow for adjustable G-force, enabling operators to optimize performance for specific drilling conditions.

- Deck Angle: The combination of G-force and deck angle plays a critical role in solids transportation across the screen, so proper adjustment is essential.

Conclusion

High-G force technology has become a standard feature in modern shale shakers, offering significant improvements in solids separation efficiency, fluid recovery, and overall drilling performance. As drilling operations continue to face increasing demands for efficiency and environmental compliance, the importance of high-G force in shale shakers will only continue to grow.

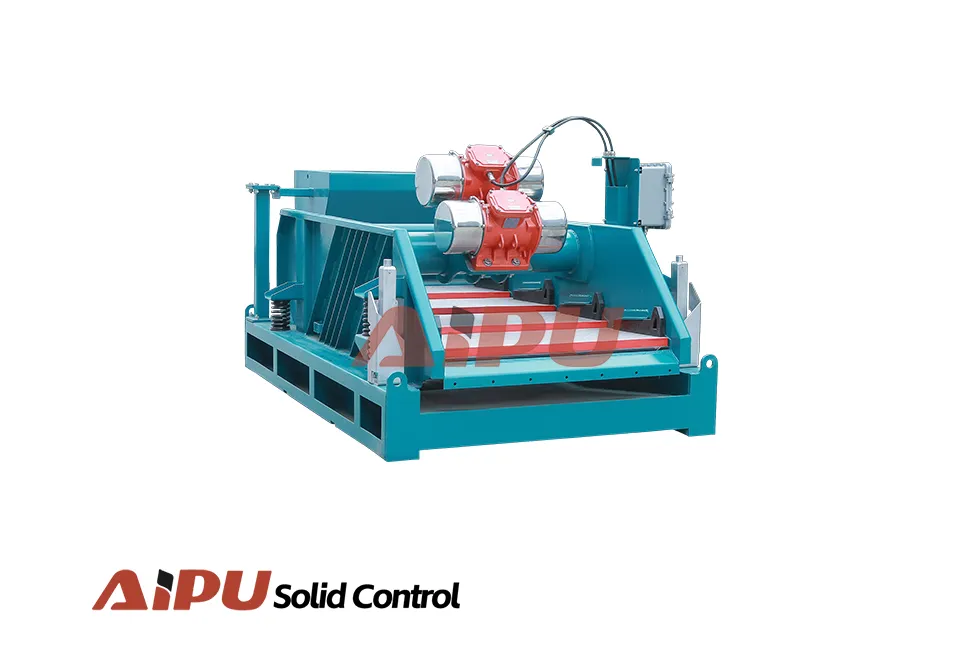

Manufacturers like AIPU Solid Control are continuously innovating to develop shale shakers with optimized G-force capabilities, ensuring that drilling operations can achieve the highest levels of performance and cost-effectiveness. By understanding the benefits and considerations of high-G force technology, operators can make informed decisions when selecting shale shakers for their specific needs.