As drilling operations continue to scale up in size and complexity, the demand for high-volume solids control equipment has never been greater. Large-scale drilling projects, such as deepwater exploration, unconventional resource development, and major infrastructure projects, generate massive volumes of drilling fluid that require efficient processing. In response to this need, tandem shale shaker systems have emerged as a powerful solution for handling extreme fluid flow rates.

Tandem shale shakers represent a significant advancement in solids control technology, offering the ability to process two or more times the volume of traditional single-unit systems. In this article, we'll explore the design, benefits, and applications of tandem shale shaker systems for high-volume drilling operations.

Understanding Tandem Shale Shaker Design

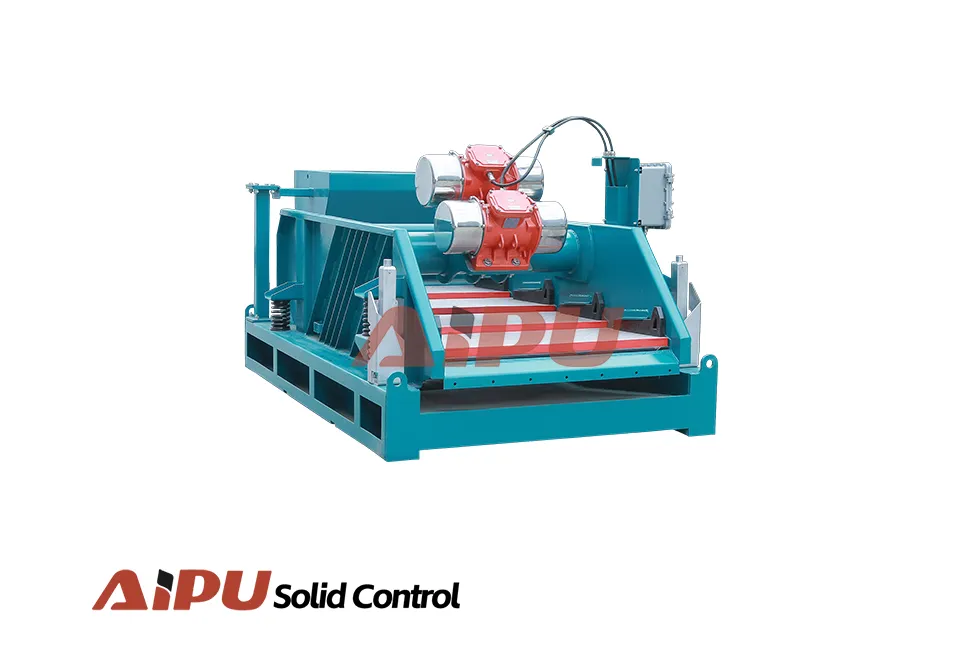

A tandem shale shaker system consists of two or more individual shale shakers connected in parallel, sharing a common feed box and fluid discharge system. This configuration allows the system to handle significantly higher fluid flow rates than a single shaker unit. The feed box is designed to distribute drilling fluid evenly across all shaker decks, ensuring balanced loading and optimal performance from each unit.

Modern tandem systems often feature synchronized operation, with all shakers running at the same vibration frequency and amplitude. This ensures consistent performance across the entire system and helps maintain uniform separation efficiency.

Key Design Features

Tandem shale shaker systems incorporate several advanced design features to optimize performance:

- Common Feed Distribution: Precision-engineered feed boxes that evenly distribute drilling fluid across all shaker decks, preventing overloading of individual units.

- Synchronized Vibration: All shakers in the system operate at the same frequency and amplitude, ensuring consistent separation performance.

- Modular Construction: Many tandem systems feature modular designs that allow for easy expansion or reconfiguration based on changing drilling requirements.

- High-G Force Capability: Individual shaker units capable of generating high G-forces for efficient separation of fine particles.

- Quick-Release Screen Systems: Easy-to-change screen systems that reduce downtime during screen replacements.

- Durable Construction: Heavy-duty frames and components designed to withstand the rigors of continuous high-volume operation.

"Tandem shale shaker systems have revolutionized solids control for large-scale drilling operations, enabling efficient processing of fluid volumes that were previously challenging or impossible to handle with single-unit systems."

- Drilling Operations Expert

Benefits of Tandem Shale Shaker Systems

The tandem configuration offers several significant advantages over traditional single-shaker systems, particularly for high-volume drilling operations:

1. Increased Processing Capacity

The primary benefit of tandem shale shakers is their ability to handle significantly higher fluid flow rates. A two-unit tandem system can typically process 150-200% of the volume of a single unit, while larger multi-unit systems can handle even greater volumes.

2. Enhanced Separation Efficiency

By distributing fluid across multiple shaker decks, tandem systems can achieve more thorough separation than single units. Each shaker deck can focus on specific particle sizes, resulting in cleaner drilling fluid and better overall solids control.

3. Improved Reliability and Redundancy

Tandem systems offer built-in redundancy, meaning that if one shaker unit experiences a problem, the remaining units can continue operating, reducing the risk of complete system failure and minimizing downtime.

4. Flexible Configuration Options

Many tandem systems are designed with modular components, allowing operators to configure the system based on specific drilling requirements. This flexibility makes them suitable for a wide range of drilling applications and fluid conditions.

5. Reduced Capital and Operating Costs

While tandem systems have a higher initial capital cost than single units, they often offer lower operating costs over time. The increased efficiency and reduced downtime can result in significant savings, particularly for long-term drilling projects.

6. Better Drilling Fluid Conservation

By processing drilling fluid more efficiently, tandem systems help conserve valuable drilling fluid, reducing the need for frequent makeup fluid additions and minimizing waste.

Applications of Tandem Shale Shaker Systems

Tandem shale shaker systems are well-suited for a wide range of high-volume drilling applications, including:

1. Deepwater and Ultra-Deepwater Drilling

These operations generate massive volumes of drilling fluid, often requiring processing rates of 200 m椴?h or more. Tandem systems are ideal for handling these extreme flow rates while maintaining efficient solids separation.

2. Unconventional Resource Development

Hydraulic fracturing operations for shale gas and oil require large volumes of drilling and completion fluids. Tandem shale shakers can efficiently process these fluids, helping to reduce costs and minimize environmental impact.

3. Horizontal Directional Drilling (HDD)

Large-scale HDD projects, such as pipeline installations and utility crossings, generate significant volumes of drilling fluid that must be processed efficiently to maintain project schedules.

4. Mining and Construction Drilling

Major mining and construction projects, such as open-pit mining and tunnel boring, require continuous processing of large volumes of drilling fluid. Tandem systems can handle these demands while maintaining reliable performance.

5. Geothermal Drilling

Geothermal drilling operations often involve high-temperature drilling fluids and abrasive cuttings. Tandem systems with durable construction and high-G force capabilities are ideal for these challenging conditions.

Choosing the Right Tandem Shale Shaker System

When selecting a tandem shale shaker system for your operation, consider the following factors:

- Processing Capacity: Ensure the system can handle your expected maximum fluid flow rates, with a safety margin to accommodate fluctuations.

- Separation Efficiency: Look for systems with high-G force capabilities and advanced screen technology to ensure efficient solids removal.

- Modularity: Choose a system that can be easily expanded or reconfigured to adapt to changing drilling requirements.

- Reliability: Select a system with a proven track record of reliable performance in similar applications.

- Maintenance Requirements: Consider the ease of maintenance and availability of replacement parts for the system.

- Manufacturer Support: Choose a reputable manufacturer with strong customer support and a global service network.

Best Practices for Operating Tandem Shale Shaker Systems

To maximize the performance and lifespan of your tandem shale shaker system, follow these best practices:

1. Ensure Proper Feed Distribution

Regularly inspect and maintain the feed box to ensure even distribution of drilling fluid across all shaker decks. Uneven feeding can lead to overloading of individual units and reduced overall performance.

2. Use Quality Screens

Invest in high-quality screens with the appropriate mesh size for your drilling conditions. Poor-quality screens can reduce separation efficiency and increase operating costs.

3. Maintain Proper Vibration Settings

Ensure all shakers in the system are operating at the same frequency and amplitude. Regularly calibrate vibration settings to maintain optimal performance.

4. Implement a Regular Maintenance Schedule

Follow the manufacturer's recommended maintenance schedule, including regular inspections, lubrication, and component replacements.

5. Train Personnel Properly

Ensure that all personnel responsible for operating and maintaining the tandem system receive proper training on its operation, maintenance, and troubleshooting.

Conclusion

Tandem shale shaker systems represent a significant advancement in solids control technology, offering the ability to efficiently process massive volumes of drilling fluid for large-scale operations. Their increased capacity, enhanced separation efficiency, and improved reliability make them an invaluable asset for modern high-volume drilling projects.

As drilling operations continue to scale up in size and complexity, tandem shale shaker systems will likely play an increasingly important role in solids control. Their ability to handle extreme fluid flow rates while maintaining efficient separation makes them a critical component of any large-scale drilling operation seeking to optimize performance, reduce costs, and minimize environmental impact.

By understanding the design, benefits, and applications of tandem shale shaker systems, drilling operators can make informed decisions about implementing this technology in their operations, ultimately improving efficiency and profitability.