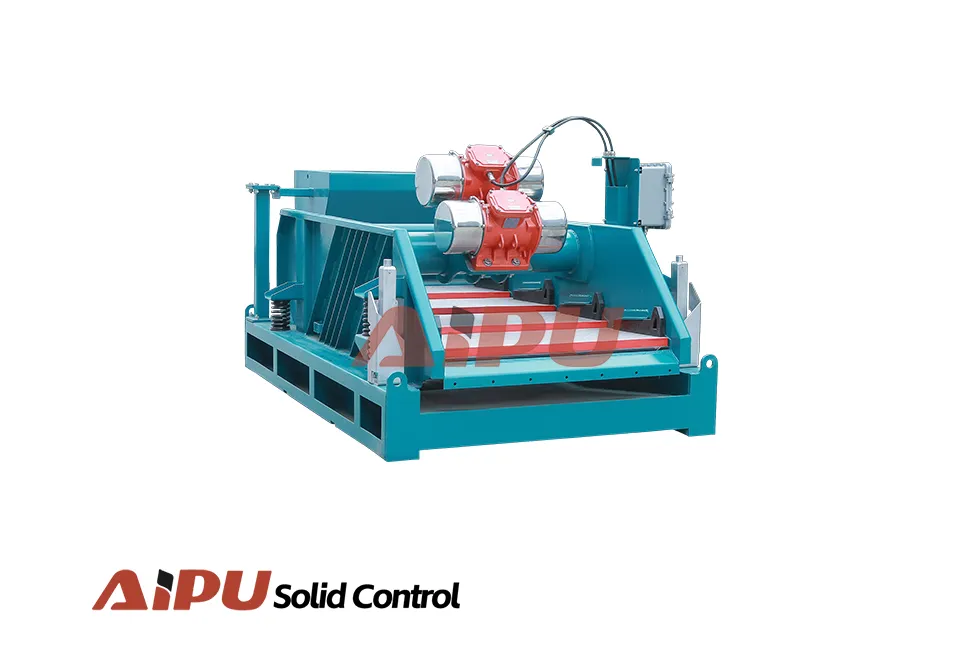

In the evolving landscape of drilling technology, the shale shaker remains the cornerstone of efficient solids control systems. Among the various types available, dual motion shale shakers have emerged as a versatile solution, offering operators the flexibility to adapt to changing drilling conditions while maintaining optimal performance.

Unlike traditional single-motion shakers, dual motion models combine the benefits of both linear and elliptical motion, allowing operators to switch between these modes based on the specific requirements of their drilling operation. This adaptability makes dual motion shakers particularly valuable in challenging drilling environments where conditions can vary significantly.

Understanding Dual Motion Technology

Dual motion shale shakers utilize advanced vibratory mechanisms that can be adjusted to produce either linear or elliptical motion. This versatility is achieved through sophisticated design features that allow for easy mode switching without requiring extensive downtime or equipment modifications.

In linear motion mode, the shaker generates straight-line vibrations that are ideal for handling high-volume drilling fluid flow. This mode excels at quickly removing large cuttings from the fluid, making it suitable for primary solids separation in many drilling applications.

Elliptical Motion Benefits

When operating in elliptical motion mode, the shaker produces a more complex vibration pattern that combines both horizontal and vertical movements. This mode offers several advantages:

- Improved cuttings transport across the screen surface

- Enhanced separation efficiency for finer particles

- Reduced screen blinding and plugging

- Better handling of viscous drilling fluids

- Longer screen life due to more uniform wear

"The ability to switch between motion modes on a dual motion shale shaker provides drilling operators with unprecedented flexibility, allowing them to optimize performance for each phase of the drilling process."

- Drilling Technology Expert

Applications of Dual Motion Shale Shakers

Dual motion shale shakers are well-suited for a wide range of drilling applications, including:

Oil and Gas Drilling

In traditional oil and gas drilling operations, dual motion shakers can adapt to changing formations, from soft clays to hard rock. This adaptability ensures consistent performance throughout the drilling process.

Horizontal Directional Drilling (HDD)

For HDD applications, where drilling fluid properties can vary significantly, dual motion shakers provide the flexibility needed to maintain efficient solids separation while minimizing fluid loss.

Geothermal Drilling

Geothermal drilling often involves high-temperature drilling fluids and abrasive cuttings. Dual motion shakers can be adjusted to handle these challenging conditions effectively.

Mining and Construction

In mining and construction drilling, where large volumes of drilling fluid and cuttings are common, dual motion shakers excel at handling high flow rates while maintaining efficient separation.

Key Advantages of Dual Motion Shale Shakers

The versatility of dual motion shale shakers offers several significant advantages to drilling operators:

1. Enhanced Performance Across Multiple Conditions

By switching between linear and elliptical motion, operators can optimize the shaker's performance for different drilling fluids, cuttings types, and flow rates.

2. Improved Screen Life

The more uniform wear patterns achieved with dual motion technology can extend screen life, reducing operating costs and downtime associated with screen replacement.

3. Reduced Fluid Loss

Better solids separation efficiency means less drilling fluid is lost with the cuttings, resulting in significant cost savings over the course of a drilling project.

4. Increased Productivity

With fewer screen changes and less downtime for maintenance, dual motion shakers can help increase overall drilling productivity.

5. Environmental Benefits

Improved solids separation reduces the volume of waste generated, making dual motion shakers a more environmentally friendly option compared to less efficient solids control equipment.

Conclusion

As drilling operations continue to face increasing challenges, the versatility and performance of dual motion shale shakers make them an attractive option for operators seeking to optimize their solids control systems. By combining the benefits of both linear and elliptical motion, these shakers provide the adaptability needed to maintain efficient performance across a wide range of drilling conditions.

Whether used in traditional oil and gas drilling, HDD, geothermal, or mining applications, dual motion shale shakers offer operators a competitive edge by improving productivity, reducing costs, and minimizing environmental impact. As technology continues to advance, we can expect to see further refinements in dual motion shaker design, enhancing their capabilities and making them an even more valuable component of modern drilling operations.