As the global drilling industry continues to prioritize sustainability and environmental responsibility, the role of efficient solids control equipment has become increasingly important. Among these critical components, shale shakers play a fundamental role in promoting sustainable drilling practices. By optimizing drilling fluid management, reducing waste generation, and minimizing environmental impact, modern shale shakers are helping drilling operators achieve their sustainability goals while maintaining operational efficiency.

Understanding the specific ways in which shale shakers contribute to sustainable drilling can help operators make informed decisions about their solids control systems, ultimately leading to more environmentally friendly and cost-effective operations.

Key Contributions of Shale Shakers to Sustainable Drilling

Modern shale shakers contribute to sustainable drilling practices in several significant ways:

1. Efficient Drilling Fluid Recycling

One of the most important contributions of shale shakers to sustainability is their ability to efficiently recycle drilling fluid. Drilling fluid, also known as mud, is a critical component of drilling operations, but it can be expensive and environmentally impactful if not properly managed.

High-performance shale shakers effectively separate drill cuttings from the drilling fluid, allowing for up to 98% of the fluid to be recycled and reused. This reduces the need for fresh fluid, minimizing both the environmental impact of fluid production and the associated costs.

"Our modern shale shaker system has enabled us to reduce fresh drilling fluid consumption by 65%, significantly lowering our environmental footprint and operational costs. This has been a game-changer for our sustainability initiatives."

2. Reduced Waste Generation

By efficiently separating solids from drilling fluid, shale shakers also help reduce the volume of waste generated during drilling operations. The separated cuttings are drier and more stable, making them easier to handle and dispose of in an environmentally responsible manner.

Modern shale shakers with high-G force capabilities and advanced screen technology can produce cuttings with lower fluid content, reducing the volume of waste that requires special handling or treatment. This not only minimizes environmental impact but also reduces waste disposal costs.

3. Lower Energy Consumption

Recent advancements in shale shaker design have focused on improving energy efficiency. Modern shakers feature optimized vibration systems, energy-efficient motors, and improved balance, resulting in lower energy consumption compared to older models.

Some advanced shale shakers also incorporate variable frequency drives (VFDs) that allow operators to adjust vibration intensity based on drilling conditions, further optimizing energy usage. Reduced energy consumption not only lowers operational costs but also decreases the carbon footprint of drilling operations.

4. Reduced Chemical Usage

Efficient solids separation by shale shakers can also lead to reduced chemical usage in drilling operations. When drilling fluid is effectively cleaned by the shale shaker, it requires fewer chemical additives to maintain its properties, reducing both costs and environmental impact.

Additionally, cleaner drilling fluid can improve drilling performance, reducing the need for chemical treatments to address issues such as lost circulation or wellbore instability.

5. Improved Wellbore Stability and Formation Protection

Proper solids control by shale shakers helps maintain the integrity of the wellbore and protect the surrounding formation. When drilling fluid properties are maintained through efficient solids separation, the fluid can better support the wellbore and prevent formation damage.

This improved wellbore stability reduces the risk of drilling incidents and environmental issues, while also promoting more efficient drilling operations.

Advanced Shale Shaker Technologies for Sustainability

Several advanced shale shaker technologies are specifically designed to enhance sustainability in drilling operations:

High-Efficiency Screen Technology

Modern shale shaker screens feature improved designs and materials that provide better solids separation efficiency. These screens can handle finer mesh sizes while maintaining high throughput, allowing for more effective fluid cleaning and reduced waste generation.

Adjustable G-Force Systems

Shale shakers with adjustable G-force systems allow operators to optimize vibration intensity based on drilling conditions. This not only improves separation efficiency but also reduces energy consumption by using only the necessary force for the specific application.

Dual-Motion Technology

Dual-motion shale shakers can switch between linear and elliptical motion, providing versatility for different drilling conditions. This allows operators to optimize performance for maximum fluid recovery and minimum waste generation in varying formation types.

Automated Monitoring and Control

Some modern shale shakers incorporate automated monitoring and control systems that continuously optimize performance based on real-time data. These systems can adjust vibration parameters, screen tension, and other settings to maintain optimal separation efficiency, reducing energy consumption and improving fluid recovery.

Best Practices for Maximizing Shale Shaker Sustainability

To maximize the sustainability benefits of shale shakers, operators should follow these best practices:

- Invest in high-performance, energy-efficient shale shaker systems

- Use advanced screen technology appropriate for the drilling conditions

- Optimize G-force and vibration settings for maximum efficiency

- Implement regular maintenance programs to ensure optimal performance

- Train operators on proper shale shaker operation and optimization

- Monitor and analyze performance data to identify opportunities for improvement

Conclusion

Shale shakers play a critical role in promoting sustainable drilling practices, helping operators reduce environmental impact while maintaining operational efficiency and cost-effectiveness. Through efficient fluid recycling, reduced waste generation, lower energy consumption, and improved wellbore stability, modern shale shakers are essential components of sustainable drilling operations.

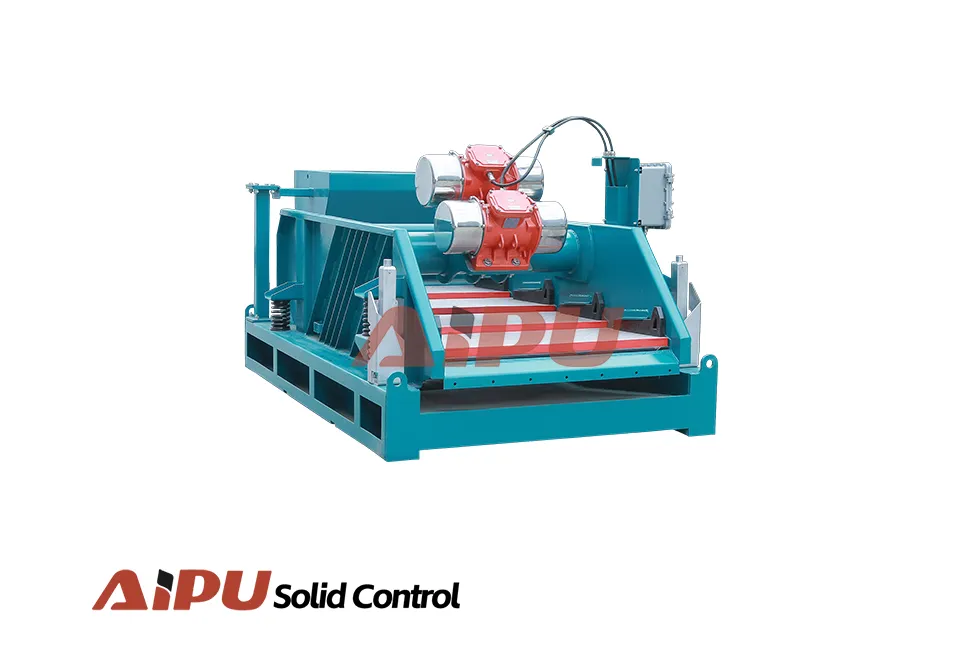

As the drilling industry continues to evolve and prioritize sustainability, the importance of advanced shale shaker technology will only increase. Manufacturers like AIPU Solid Control are at the forefront of this evolution, developing innovative shale shaker solutions that meet the growing demand for sustainable drilling practices.

By investing in modern shale shaker technology and implementing best practices for operation and maintenance, drilling operators can significantly improve their sustainability performance, reduce environmental impact, and achieve their operational goals in a more responsible manner.