Horizontal Directional Drilling (HDD) has revolutionized the installation of underground utilities, pipelines, and cables. This trenchless technology offers numerous advantages, including minimal surface disruption, reduced environmental impact, and faster installation times. However, HDD operations generate significant volumes of drilling fluid and cuttings that require efficient management. Shale shakers play a critical role in this process, serving as the primary solids control equipment for HDD operations.

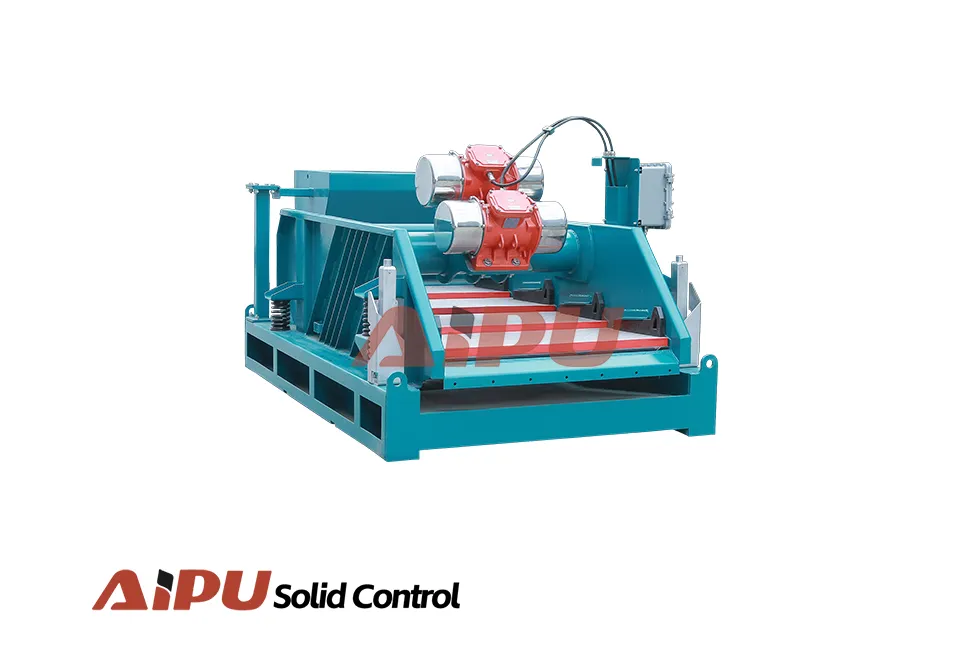

Specialized HDD shale shakers are designed to handle the unique challenges of horizontal drilling, including high-volume fluid flow, varying soil conditions, and the need for efficient fluid recycling. Understanding how these specialized shakers work and their key features can help HDD contractors optimize their operations and reduce costs.

Unique Challenges of HDD Solids Control

HDD operations present several unique challenges for solids control systems:

- High Fluid Volumes: HDD rigs typically use large volumes of drilling fluid (bentonite or polymer-based) to lubricate the drill bit, stabilize the borehole, and carry cuttings to the surface.

- Variable Soil Conditions: HDD projects often encounter multiple soil types, from sand and clay to rock, resulting in varying cutting sizes and properties.

- Space Constraints: HDD sites often have limited space for equipment, requiring compact and mobile solids control systems.

- Fluid Recycling Requirements: Efficient fluid recycling is essential for HDD profitability, as fresh drilling fluid can account for a significant portion of project costs.

- Environmental Regulations: HDD operations must comply with strict environmental regulations regarding drilling fluid disposal and site cleanup.

Specialized Features of HDD Shale Shakers

Shale shakers designed for HDD applications incorporate several specialized features to address these challenges:

"HDD-specific shale shakers have been a game-changer for our operations. They handle high fluid volumes efficiently, allowing us to recycle more than 95% of our drilling fluid, which has significantly reduced our operational costs."

High Capacity Design

HDD shale shakers are built with larger screen areas and higher vibration intensities to handle the high-volume fluid flow typical of HDD operations. Many models feature dual or triple-deck designs to increase separation efficiency and capacity.

Adjustable Vibration Parameters

The ability to adjust vibration intensity (G-force) and frequency allows operators to optimize shaker performance for different soil conditions. Higher G-forces are effective for heavy, dense cuttings, while lower G-forces are better for lighter, finer materials.

Compact and Mobile Design

HDD shale shakers are typically mounted on skids or trailers, making them easy to transport between job sites. Compact designs maximize space utilization, a critical factor for HDD operations with limited site space.

Specialized Screen Systems

HDD shale shakers use specialized screen designs optimized for the fine cuttings generated in horizontal drilling. Many models feature quick-replace screen systems for fast and easy screen changes, minimizing downtime.

Corrosion Resistance

HDD drilling fluids can be corrosive, especially polymer-based fluids. Shale shakers designed for HDD applications incorporate corrosion-resistant materials, such as stainless steel, to prolong equipment life.

Benefits of Using Specialized HDD Shale Shakers

The use of specialized HDD shale shakers offers several significant benefits for HDD contractors:

Improved Fluid Recycling

Efficient solids separation allows for more effective fluid recycling, reducing the need for fresh fluid purchases and disposal costs. This can result in cost savings of 30-50% on fluid-related expenses.

Reduced Environmental Impact

By maximizing fluid recycling and minimizing waste generation, specialized HDD shale shakers help contractors comply with environmental regulations and reduce their overall environmental footprint.

Increased Drilling Efficiency

Clean, properly conditioned drilling fluid improves drilling performance, reduces equipment wear, and minimizes the risk of borehole instability. This can lead to faster drilling rates and fewer operational issues.

Lower Operational Costs

The combination of improved fluid recycling, reduced waste disposal, and increased drilling efficiency results in lower overall operational costs for HDD projects.

Enhanced Reliability

Specialized HDD shale shakers are built to withstand the demanding conditions of HDD operations, resulting in improved reliability and reduced maintenance requirements.

Best Practices for HDD Shale Shaker Operation

To maximize the performance and longevity of HDD shale shakers, contractors should follow these best practices:

- Select the Right Shaker for the Job: Choose a shale shaker with appropriate capacity and features for the specific HDD project requirements.

- Use the Correct Screen Mesh: Select screen mesh sizes based on the soil conditions and drilling fluid properties to optimize separation efficiency.

- Maintain Proper G-force Settings: Adjust vibration intensity based on the type of cuttings being processed.

- Regularly Inspect and Clean Screens: Inspect screens frequently for damage or blinding, and clean them regularly to maintain optimal performance.

- Train Operators Properly: Ensure operators are trained in the proper operation and maintenance of the shale shaker.

- Implement a Preventive Maintenance Program: Regular maintenance, including lubrication, vibration motor inspection, and screen replacement, can extend the life of the equipment.

Conclusion

Shale shakers are essential components of HDD solids control systems, playing a critical role in efficient fluid management and waste reduction. Specialized HDD shale shakers are designed to address the unique challenges of horizontal directional drilling, including high fluid volumes, variable soil conditions, and space constraints.

By investing in high-quality, specialized HDD shale shakers, contractors can improve fluid recycling rates, reduce operational costs, and minimize their environmental impact. Manufacturers like AIPU Solid Control are at the forefront of HDD shale shaker technology, developing innovative solutions that meet the evolving needs of the HDD industry.

As HDD technology continues to advance and projects become more complex, the importance of efficient solids control will only increase. Specialized shale shakers will remain a critical component of successful HDD operations, helping contractors meet their performance, cost, and environmental goals.