Linear motion shale shakers are the most widely used type of shale shaker in the drilling industry. Known for their reliability, efficiency, and versatility, these machines form the backbone of solids control systems in oil & gas drilling, HDD, and various industrial applications. Understanding how linear motion shale shakers work and their key features can help operators optimize their performance and reduce operational costs.

Linear motion shale shakers derive their name from the linear vibration pattern they produce. Unlike circular or elliptical motion shakers, linear motion models generate a straight-line vibration that moves cuttings across the screen from feed end to discharge end. This design offers several advantages for solids separation.

Working Principles of Linear Motion Shale Shakers

Linear motion shale shakers operate on a simple yet effective principle. Two counter-rotating eccentric weights create a balanced linear vibration force that is transmitted to the shaker deck. This force causes the screen to vibrate in a straight line, typically at an angle of 5-7 degrees relative to the horizontal plane.

When drilling fluid enters the shaker, the linear vibration creates a fluid bed on the screen surface. The combination of vibration and gravity causes:

- Fines particles to pass through the screen mesh into the fluid collection tank

- Coarser cuttings to move across the screen to the discharge end

- Effective separation of solids from the drilling fluid

Key Components of Linear Motion Shale Shakers

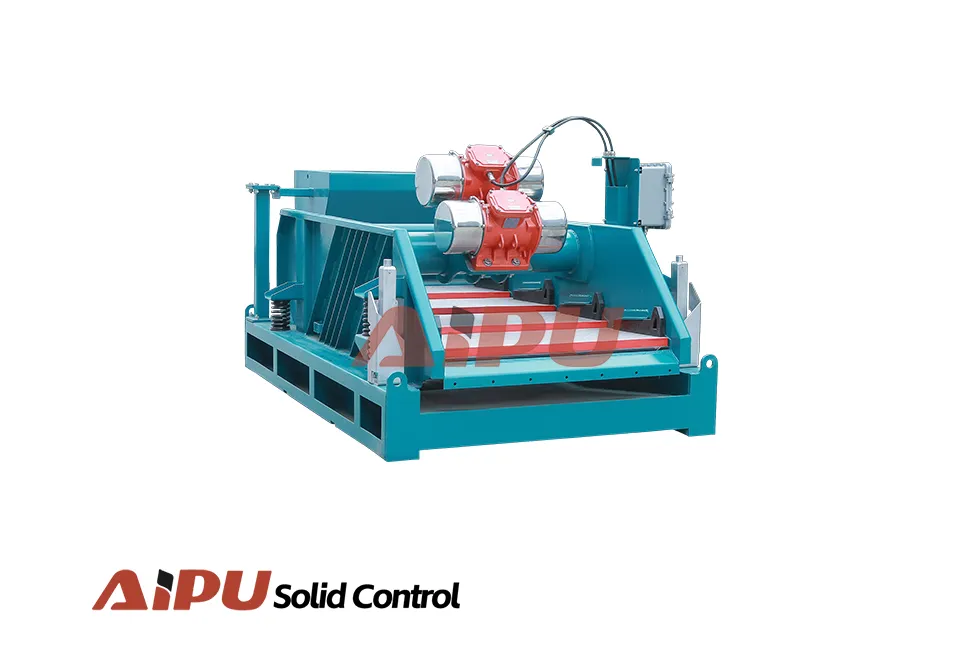

A typical linear motion shale shaker consists of several critical components:

Shaker Deck

The shaker deck holds the screen panels and is responsible for transmitting vibration to the screen. Modern decks are usually constructed from durable materials like steel or aluminum and feature adjustable angles to optimize cuttings transportation.

"Linear motion shale shakers are favored for their ability to handle high-volume drilling fluid while maintaining excellent solids separation efficiency, making them ideal for primary solids control in most drilling applications."

Vibration Motors

Two counter-rotating vibration motors generate the linear motion. These motors are typically mounted on opposite sides of the shaker deck and synchronized to produce balanced vibration. The motor speed and eccentric weight can be adjusted to control the vibration intensity (G-force).

Screen System

The screen system is the heart of the shale shaker, responsible for actual solids separation. Linear motion shakers typically use multi-panel screen designs with quick-lock mechanisms for easy replacement. Screen panels are available in various mesh sizes to accommodate different drilling conditions.

Fluid Collection System

This system collects the separated drilling fluid and directs it to the next stage of the solids control system. It includes a trough or tank located beneath the screen deck.

Advantages of Linear Motion Shale Shakers

Linear motion shale shakers offer several key advantages over other types of shakers:

High Capacity

The linear vibration pattern allows for efficient handling of high-volume drilling fluid, making these shakers ideal for primary solids control in large-scale drilling operations.

Consistent Solids Separation

The linear motion creates a uniform fluid bed across the screen surface, ensuring consistent separation efficiency across the entire screen area.

Longer Screen Life

The balanced vibration and uniform loading reduce screen wear, extending screen life and reducing maintenance costs.

Versatility

Linear motion shakers perform well in a wide range of drilling conditions, from oil & gas to HDD and industrial applications.

Easy Maintenance

Modern linear motion shakers feature quick-replace screen systems and accessible components, minimizing downtime for maintenance and screen changes.

Applications of Linear Motion Shale Shakers

Linear motion shale shakers are suitable for various applications:

- Onshore and offshore oil & gas drilling

- Horizontal Directional Drilling (HDD)

- Geothermal drilling

- Mineral exploration

- Industrial slurry separation

- Wastewater treatment

Optimizing Linear Motion Shale Shaker Performance

To maximize the efficiency of a linear motion shale shaker, operators should consider:

- Selecting the appropriate screen mesh size for the drilling conditions

- Adjusting the deck angle to optimize cuttings transportation

- Setting the correct G-force for the drilling fluid properties

- Maintaining proper feed rate to avoid screen overloading

- Regularly inspecting and maintaining vibration motors

- Replacing worn screens promptly to maintain separation efficiency

Conclusion

Linear motion shale shakers remain the workhorse of solids control systems in the drilling industry. Their simple design, reliable performance, and versatility make them suitable for a wide range of applications.

Manufacturers like AIPU Solid Control continue to innovate linear motion shale shaker technology, incorporating features like adjustable G-force, quick-replace screens, and durable construction to meet the evolving needs of modern drilling operations.

By understanding the working principles, components, and advantages of linear motion shale shakers, drilling operators can make informed decisions when selecting and operating these critical pieces of equipment, ensuring optimal solids control performance and reduced operational costs.