Selecting the right shale shaker for your drilling operation is a critical decision that directly impacts drilling efficiency, fluid management, and overall operational costs. As the first line of defense in solids control, the shale shaker plays a pivotal role in maintaining drilling fluid properties and protecting downstream equipment. This comprehensive guide outlines the key factors to consider when choosing a shale shaker that meets your specific drilling requirements.

1. Assess Your Drilling Fluid Volume and Flow Rate

The first step in selecting a shale shaker is to determine your drilling fluid volume and flow rate. This information will help you choose a shaker with the appropriate capacity to handle the amount of drilling fluid your operation generates. Consider factors such as:

- The maximum anticipated flow rate of drilling fluid

- The type and viscosity of drilling fluid you're using

- The anticipated solids loading in the return fluid

A shale shaker that is undersized for your operation will lead to overflow, reduced separation efficiency, and increased wear on downstream equipment. Conversely, an oversized shaker may result in unnecessary energy consumption and higher upfront costs.

2. Evaluate Screen Efficiency and Durability

The screen is the heart of the shale shaker, responsible for separating solids from drilling fluid. When evaluating screens, consider:

- Mesh Size: Choose a screen mesh size that matches the particle size you need to remove. Smaller mesh sizes remove finer particles but may reduce fluid throughput.

- Screen Material: High-quality screens made from durable materials like stainless steel or composite materials offer longer service life and better performance.

- Screen Design: Look for screens with optimized open area for maximum fluid throughput while maintaining separation efficiency.

- Quick-Change Capability: Screens that can be easily and quickly replaced minimize downtime during screen changes.

Investing in high-quality screens can significantly reduce operating costs by minimizing screen replacement frequency and improving separation efficiency.

3. Consider Vibration Type and Intensity

Shale shakers use different vibration types to transport solids across the screen surface. The most common types include:

- Linear Motion Shakers: These shakers use linear vibration to transport solids, making them versatile and suitable for most drilling applications. They offer good balance between solids transport and fluid separation.

- Dual Motion Shakers: These shakers can switch between linear and elliptical motion, providing flexibility for different drilling conditions. They excel in handling high solids loading and sticky drilling fluids.

- Circular Motion Shakers: These shakers use circular vibration, which is effective for handling high-viscosity drilling fluids but may have lower throughput compared to linear motion shakers.

Additionally, consider the vibration intensity (G-force) of the shaker. Higher G-forces can improve solids separation but may also increase wear on components. Choose a G-force level appropriate for your specific drilling conditions.

4. Determine Compatibility with Your Solids Control System

Ensure the shale shaker you choose is compatible with your existing solids control system. Consider:

- The physical dimensions and weight of the shaker, ensuring it fits within your rig's footprint

- The connection points for drilling fluid inlet and outlet

- Compatibility with downstream equipment such as desanders, desilters, and centrifuges

- Power requirements and availability on your rig

Choosing a shaker that integrates seamlessly with your existing system will minimize installation costs and ensure optimal performance.

5. Evaluate Maintenance Requirements and Service Support

Regular maintenance is essential for keeping your shale shaker operating at peak efficiency. Consider:

- The ease of access to critical components for maintenance

- The availability and cost of replacement parts

- The manufacturer's reputation for quality and reliability

- The availability of technical support and service from the manufacturer or distributor

A shale shaker with low maintenance requirements and readily available support can significantly reduce downtime and operating costs over its lifetime.

6. Consider Environmental Regulations and Requirements

Environmental regulations are becoming increasingly stringent in many regions. Choose a shale shaker that helps you comply with local environmental requirements by:

- Maximizing solids removal efficiency to reduce waste volume

- Minimizing fluid loss and spillage

- Reducing noise levels, especially for onshore operations near populated areas

Investing in an environmentally friendly shale shaker can help you avoid costly fines and demonstrate your commitment to sustainable drilling practices.

7. Evaluate Total Cost of Ownership

When comparing shale shakers, look beyond the upfront purchase price and consider the total cost of ownership, including:

- Energy consumption

- Maintenance costs

- Screen replacement costs

- Downtime costs due to maintenance or repairs

- Cost of replacing downstream equipment due to poor shaker performance

A higher upfront investment in a quality shale shaker may result in lower total ownership costs over its lifetime due to improved efficiency, reduced maintenance, and longer service life.

Conclusion

Choosing the right shale shaker for your drilling operation requires careful consideration of multiple factors, including capacity, screen efficiency, vibration type, compatibility, maintenance requirements, environmental compliance, and total cost of ownership.

By taking the time to evaluate your specific drilling needs and comparing different shale shaker models, you can select a shaker that optimizes solids control, reduces operational costs, and improves overall drilling efficiency. Remember that the shale shaker is the foundation of your solids control system, and investing in the right equipment will pay dividends throughout the life of your drilling operation.

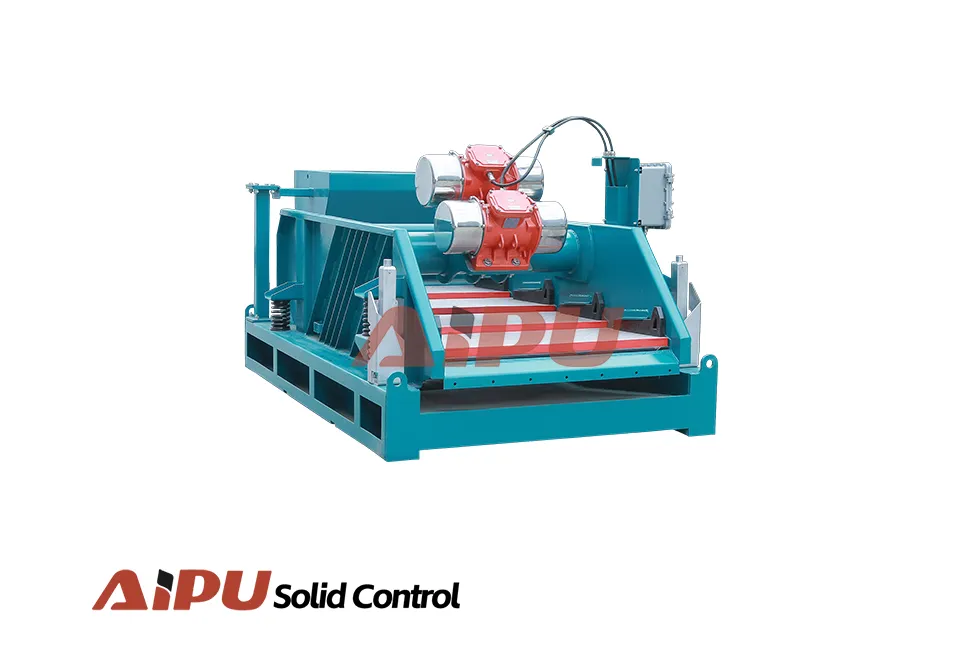

At AIPU Solids Control, we offer a comprehensive range of shale shakers designed to meet the diverse needs of modern drilling operations. Our team of experts can help you select the perfect shale shaker for your specific requirements, ensuring optimal performance and maximum return on investment.