Shale shaker screens are critical components in solids control systems, responsible for separating drill cuttings from drilling fluid. Over time, these screens become worn or damaged, requiring replacement to maintain optimal performance. Traditional screen replacement processes can be time-consuming and labor-intensive, leading to significant downtime and increased operational costs. Quick-replace screens have emerged as a solution to these challenges, offering numerous benefits for drilling operations that rely on shale shakers.

Quick-replace screens feature innovative designs that allow for fast and easy screen changes, reducing downtime from hours to minutes. This technology has revolutionized maintenance practices in the drilling industry, improving efficiency and reducing costs across the board.

Key Benefits of Quick-Replace Screens

The adoption of quick-replace screens offers several significant advantages for drilling operations:

Reduced Downtime

One of the most significant benefits of quick-replace screens is the dramatic reduction in downtime. Traditional screen replacement can take 1-2 hours per shaker, while quick-replace systems allow for screen changes in as little as 5-10 minutes. This reduction in downtime translates directly to increased drilling efficiency and lower operational costs.

"Quick-replace screens have reduced our shale shaker downtime by over 70%, allowing us to maintain continuous drilling operations and meet our production targets more consistently."

Lower Labor Costs

Traditional screen replacement requires multiple workers and specialized tools. Quick-replace screens are designed for single-person operation, eliminating the need for additional labor. This reduces labor costs and allows maintenance teams to focus on other critical tasks.

Improved Safety

The quick-replace design minimizes the physical effort required for screen changes, reducing the risk of injuries such as back strains and hand injuries. Additionally, the reduced time spent on maintenance tasks in potentially hazardous drilling environments improves overall site safety.

Enhanced Screen Performance

Quick-replace screens often feature improved design elements compared to traditional screens, including better screen tensioning systems and more durable materials. This results in better solids separation efficiency and longer screen life, further reducing operational costs.

Versatility

Quick-replace screen systems are compatible with a wide range of shale shaker models, making them a versatile solution for drilling operations with multiple types of equipment. This compatibility allows operators to standardize maintenance practices across their fleet, simplifying inventory management and training.

Better Inventory Management

Quick-replace screens typically use a modular design, allowing for easier inventory management. Operators can stock fewer screen sizes while still being able to accommodate different drilling conditions, reducing storage requirements and inventory costs.

How Quick-Replace Screens Work

Quick-replace screens utilize various innovative mechanisms to facilitate fast and easy replacement. Common design features include:

- Quick-Lock Systems: Lever-based or clamp-based mechanisms that securely fasten screens to the shaker deck without the need for tools.

- Modular Design: Screens composed of multiple panels that can be replaced individually if damaged, rather than replacing the entire screen assembly.

- Self-Tensioning Systems: Mechanisms that automatically apply the correct tension to the screen mesh during installation, ensuring optimal performance.

- Lightweight Materials: Modern composites and alloys that reduce the weight of screen panels, making them easier to handle.

Types of Quick-Replace Screen Systems

There are several types of quick-replace screen systems available on the market, each with its own unique features and benefits:

Hook Strip Systems

These systems use metal hooks or strips that attach to the shaker deck, allowing screens to be quickly secured or removed. Hook strip systems are widely used and compatible with many shaker models.

Clamp Systems

Clamp systems use manual or hydraulic clamps to secure screens to the shaker deck. These systems provide excellent screen tension and are ideal for high-vibration applications.

Magnetic Systems

Magnetic quick-replace systems use powerful magnets to hold screens in place. This design allows for extremely fast screen changes but is typically only suitable for smaller shaker models.

Boltless Systems

Boltless systems eliminate the need for bolts and nuts, using innovative locking mechanisms that can be operated by hand. These systems are becoming increasingly popular due to their simplicity and speed.

Best Practices for Using Quick-Replace Screens

To maximize the benefits of quick-replace screens, operators should follow these best practices:

- Train maintenance personnel on the proper installation and removal procedures for the specific quick-replace system being used.

- Inspect screens regularly for signs of wear, damage, or blinding.

- Store spare screens in a clean, dry environment to prevent damage.

- Select the appropriate screen mesh size for the drilling conditions.

- Follow the manufacturer's recommendations for screen replacement intervals.

- Maintain proper shaker deck alignment and vibration settings to prolong screen life.

Conclusion

Quick-replace screens represent a significant advancement in shale shaker technology, offering substantial benefits in terms of reduced downtime, lower labor costs, improved safety, and enhanced performance. As drilling operations continue to face increasing pressure to improve efficiency and reduce costs, the adoption of quick-replace screen systems is likely to become more widespread.

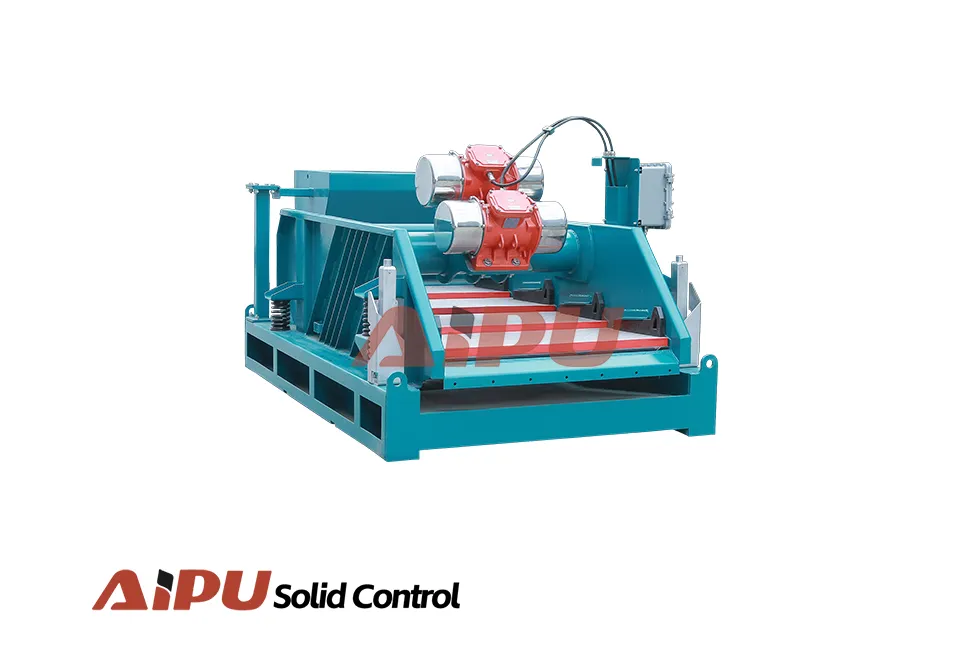

Manufacturers like AIPU Solid Control are at the forefront of this technology, developing innovative quick-replace screen solutions that meet the evolving needs of the drilling industry. By investing in quick-replace screen technology, drilling operators can improve their operational efficiency, reduce costs, and maintain a competitive edge in the global marketplace.

As the industry continues to innovate, we can expect to see further improvements in quick-replace screen technology, including even faster replacement times, more durable materials, and enhanced compatibility with a wider range of shaker models. These advancements will further solidify quick-replace screens as a standard feature in modern solids control systems.